New Circular Sock Machine Cookbook

My last blog post was over a year ago, near the beginning of the pandemic. Since then, a lot has happened. I had a stroke in April of 2020, I worked hard to recover, and then I went back to teaching full time. All the while, I’ve had patterns floating around that I wanted to make into a new CSM Cookbook. Finally, that time has arrived.

You can find The CSM Cookbook Volume Two: Fusion Recipes on Ravelry as an ebook or as individual patterns. Below is the introduction to Volume Two.

Introduction to The CSM Cookbook Volume Two: Fusion Recipes

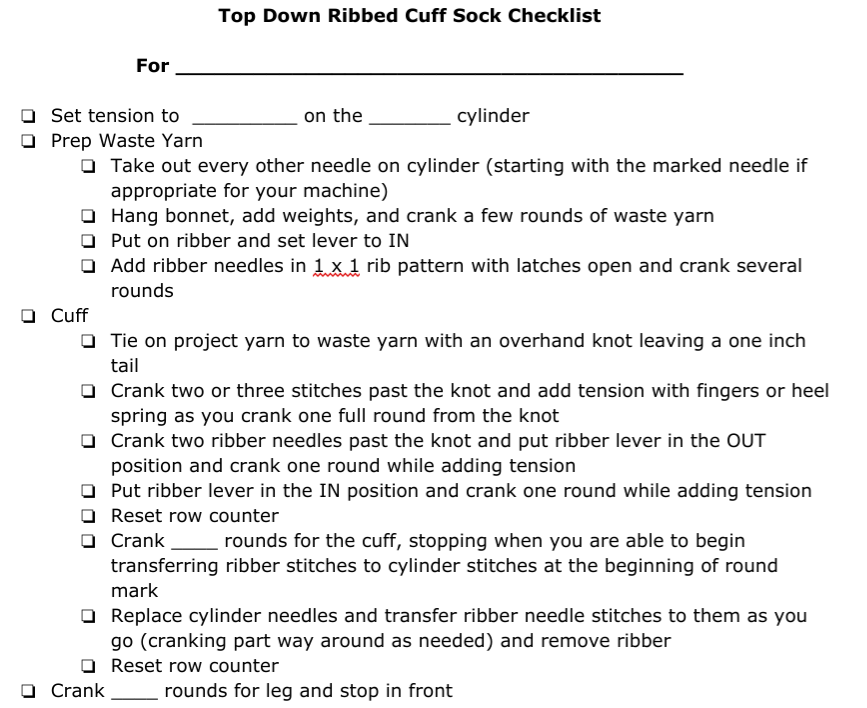

Recipe checklists started out as a way to keep myself organized. I noticed that as I learned of all the wonderful things I could make on my CSM that I would get confused or over confident and start skipping steps. I made myself some checklists so that I wouldn’t forget all the important steps to making a given item but I kept them open ended so that I could use them over and over again. From those lists came my first “cookbook” of recipes, The CSM Cookbook. However, I still had a lot of checklists left over that didn’t quite fit in a basic sock book and many of them used hand knitting or crochet for finishing. This book contains six of those patterns and includes two types of socks, mitts as well as mittens, headbands with four finishes, and a scarf with a crocheted trim. All include hand knitting or crochet after the work on the sock machine is finished so I’ve termed them “fusion recipes” that combine more than one craft just as “fusion cooking” combines more than one cuisine!

There are some things I’m expecting you to know before using these patterns:

- I’m assuming that you know how to set up your machine, adjust the tension, and get started on some waste yarn. I refer to hanging a bonnet, but however you start a sock is fine.

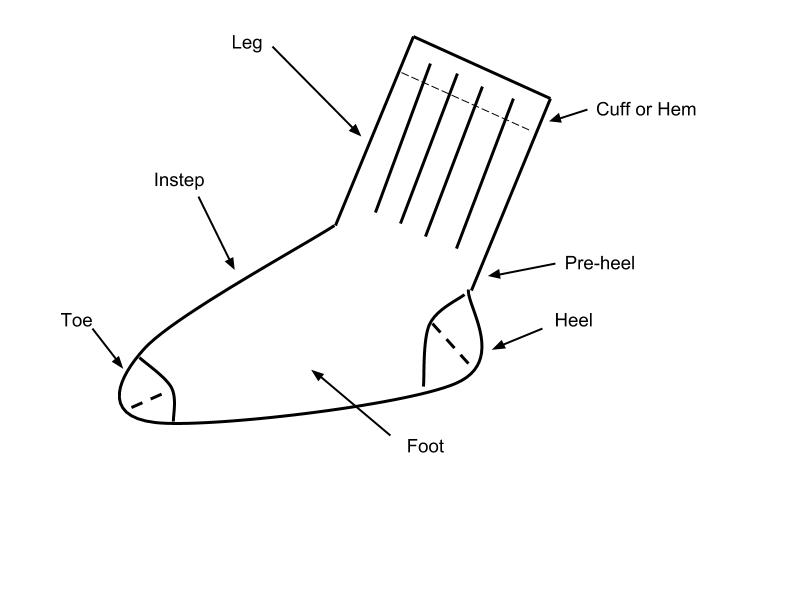

- I’m assuming that your cylinder is marked with half marks to divide the front and the back of the cylinder evenly and that both the front and the back half have target needles marked for making heels and toes.

- I’m assuming that you know how to do things like engage your heel spring and crank in both directions for heels and toes.

- Since rehanging heel forks or v-hooks while making a heel or toe depends on your particular set up, there aren’t directions for when to do this. Just move your weights when needed.

- Finally, I’m assuming that you have learned how to clean your machine, time your ribber, and adjust your yarn carriage.

If you need help with any of those things, I’ve included some of the best online instructions and videos in the Resources section of my first book, The CSM Cookbook. The first volume of the CSM Cookbook also contains directions for making gauge swatches, a worksheet to easily determine the rounds needed for a given person’s foot, and illustrations for techniques I mention in the patterns. Once you have those basic skills, these checklists will help you put them together to make beautiful socks and accessories.

I was introduced to circular sock machines as a hand knitter and knitwear designer, so you will see that I use hand knitting and US crochet terms within this book. The patterns are written in an open ended format so that you can customize the patterns to your liking.

There are many ways to accomplish a particular result on a sock machine. I’ve outlined the methods that work well for me, but please explore other methods and find the ones that are right for you. Part of the process of learning to use a sock machine is making mistakes. These checklist style patterns will help keep you from making mistakes in completing all the steps of the process, but you’ll still have plenty of dropped stitches and other errors. My advice is to take on a learner’s mindset. Go slow at first, try new methods now and then, and enjoy the process of figuring things out!

Included in this book you will find six different recipes for socks and accessories. Each recipe takes you through all the steps of making that particular item. One recipe, the Afterthought Sock, contains reproducible directions that can be included with machine knitted tubes you sell or gift to friends. This is the only pattern that you have permission to reproduce for others. The rest you may reproduce for your personal use only.

So far I’ve made two sets of mitts on my circular sock machine and they are quickly becoming my favorite project. There are no heels to turn and they are smaller than a sock so there is less cranking. I make a hole for the thumb

So far I’ve made two sets of mitts on my circular sock machine and they are quickly becoming my favorite project. There are no heels to turn and they are smaller than a sock so there is less cranking. I make a hole for the thumb

shortie sock with no ribbing. I used

shortie sock with no ribbing. I used  Next, I decided to make friends with my ribber. For the most part, I used

Next, I decided to make friends with my ribber. For the most part, I used